About Wireless Charger Magnet

The convenience of wireless charging is increasingly becoming a standard feature across various electronic products, and magnets play a crucial “precision alignment” role within this technology. They not only ensure immediate charging upon placement, enhancing the user experience, but also effectively prevent efficiency loss and energy waste caused by misalignment.

The core of our customization service is to tailor-make the perfect magnetic solution for your product’s specific needs. We provide professional support primarily through the following aspects:

- Precise Magnetic Solution Design

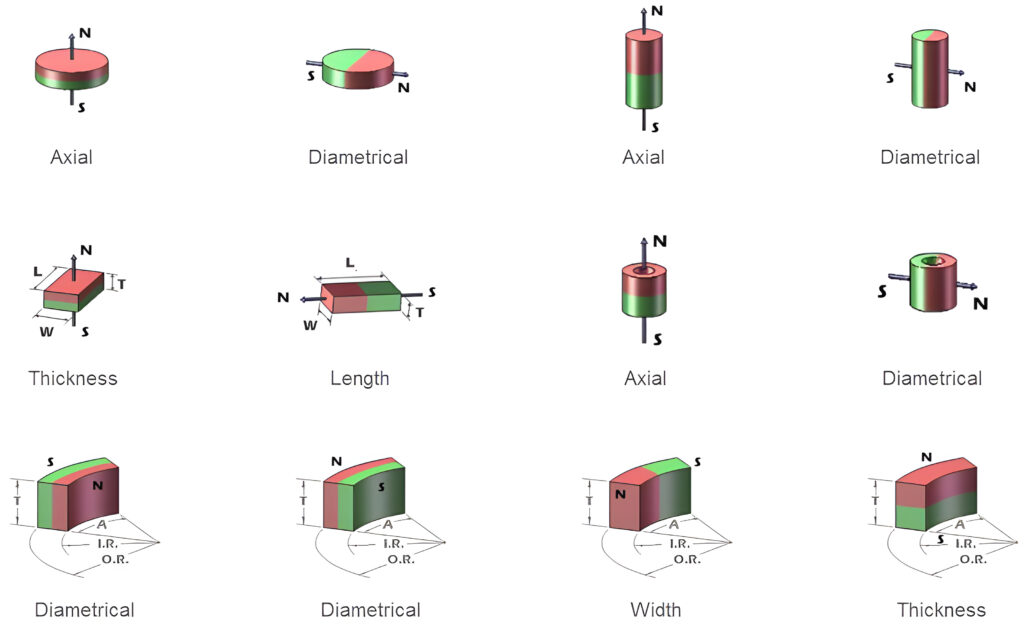

- Flexible Size and Shape Customization

- Superior Materials and Performance

- Comprehensive Surface Treatment

- Close Collaboration and Integration

Trusted By

Our products offer extensive compatibility, supporting iPhone 8 and later models (via Qi protocol) and iPhone 12 and later models (delivering the full MagSafe experience). They are also compatible with Qi wireless charging for major Android brands such as Samsung, Xiaomi, and Google. With the ongoing adoption of Qi2, we are already preparing to future-proof your products.

Wireless charger magnet Applications

Wireless charger magnet are core components in modern high-tech, widely used in wind power generation and electric vehicle motors to drive the green energy revolution. They also play a key role in enabling high efficiency and automation in industrial robots and precision CNC machinery. From household appliances to medical MRI equipment, their powerful magnetic properties bring compactness and high performance to countless products.

One-stop solution Wireless charger magnet

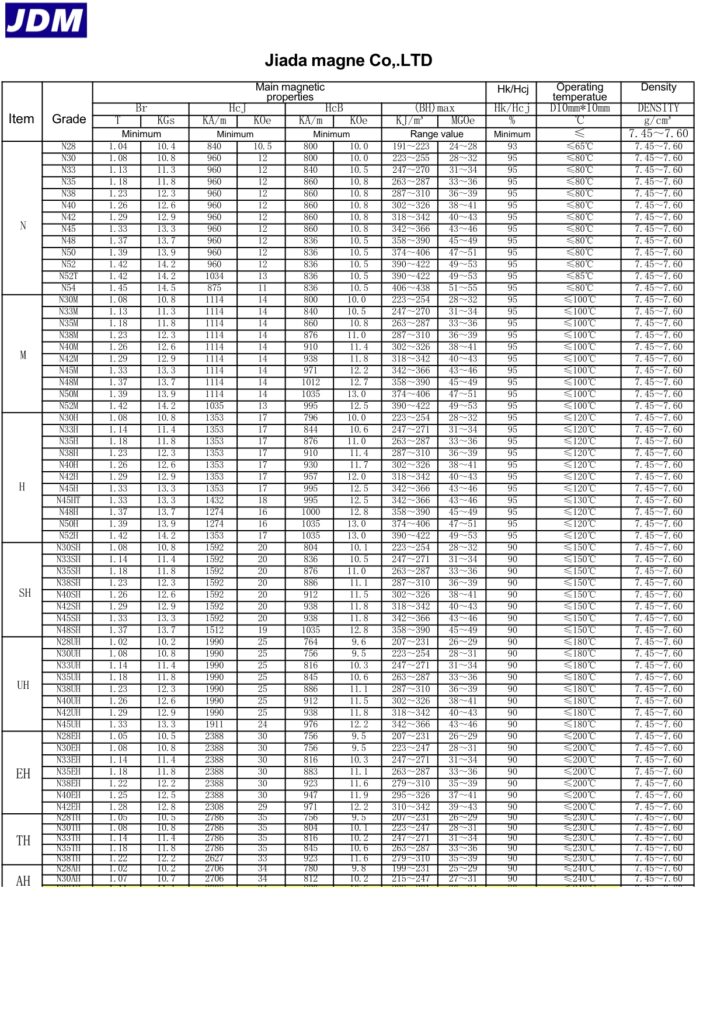

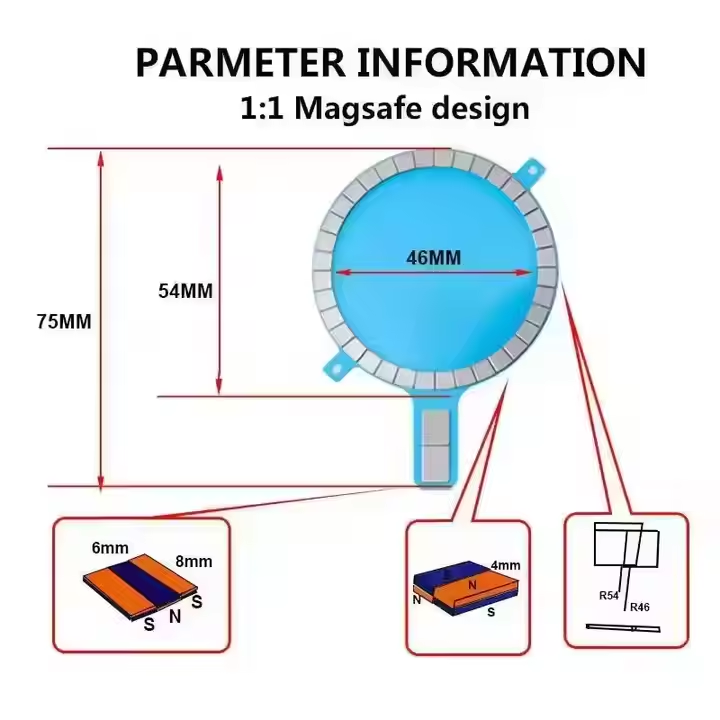

For your customization needs, we typically recommend using high-performance neodymium iron boron (NdFeB) magnets. Based on your product structure (such as phones, earbuds, or charging docks) and whether rotational alignment (e.g., MagSafe functionality) is required, we will design the optimal magnet layout, quantity, magnetic strength, and magnetization pattern. Additionally, we provide magnetic shielding sheets to form a complete and highly efficient magnetic solution.

-

Core Performance: We Ensure “Fast Charging and a Secure Hold”

-

Compatibility & Safety: Our Products are “Passports” to Global Markets

-

Customization Capability: Your Brand, Perfectly Realized By Us

-

Cost & Supply Chain: Stable, Transparent, Competitive

-

Our Commitment: Not Just a Supplier, But Your Technical Partner

Automated Assembly lines

After nearly 5 years of technical accumulation, our engineers have designed a series of equipment that can be automatically assembled, greatly improving the production efficiency and product quality of wireless magnetizing parts. We will continue to work hard to provide better service.

Get startedThis is an integrated assembly, typically composed of multiple positioning magnets (arranged in specific polarities) + a magnetic shielding sheet + magnetic conductive adhesive + a protective film, among other components. It provides customers with a complete, ”plug-and-play” magnetic solution, simplifying their assembly process and enhancing product consistency. This approach represents the current mainstream form of high-end customization.

Core Performance >>

High adsorption capacity & Precise positioning

We strictly adhere to Apple’s MagSafe magnet layout specifications, employing 16 or more high-strength neodymium (NdFeB) magnets arranged in a circular array. This ensures precise alignment and delivers a satisfying “click” upon attachment.

Excellent Thermal Stability

With surface coating treatments (such as nickel plating, etc.), it can adapt to a certain range of operating temperatures, offering good weather resistance and corrosion resistance.

High consistency and reliability

We implement full-process control through the IATF 16949 quality management system. From raw materials to finished products, we use professional equipment such as magnetic permeability testers and loop count testers for 100% inspection to ensure that the performance of each magnetic sheet is highly consistent and reliable.

Why Chooe Us?

| Customer Concerns | Industry Standard | Our Advantages | Value to You |

|---|---|---|---|

| Lead Time | 45+ days for sintered NdFeB | ✅ Dongguan Rapid Sintering Line: 10-15 days ✅ Vietnam Warehouse: 20+ standard semi-finished products (72hr emergency service) | 50% faster project launch, market advantage |

| Certifications | Basic ISO 9001 only | ⭐ Dual Certifications: • ISO 9001 (Quality) • IATF 16949 (Automotive) | Direct Tier-1 supplier qualification, no additional audits |

| Supply Chain Security | Single sourcing, price volatility | 🔒 Dual-Source System: • Hitachi Metals (Japan, premium grade) • Chinese rare earth (cost-optimized) • 3-month strategic raw material reserves | 8-15% annual cost reduction, hedge against price surges |

| Cost Optimization | No transparent annual reduction | 💰 Written Commitment: • 3-5% annual price reduction (post-ramp-up) • 30-60 days payment terms | 20%+ lifetime savings, healthier cash flow |

| Brand Flexibility | Mandatory factory branding | 🏷️ Customization Services: • Neutral packaging (no traceability) • Full OEM support (labels/certificates) • "White label" solutions for distributors | Protect channel profits, brand control |

| Technical Support | Basic spec sheets only | 🛠️ Value-Added Services: • Free magnetic circuit design • Failure analysis lab • Multilingual documentation (EN/CN/VI) | Faster R&D cycles, lower trial costs |

JDM have successively passed lS09001 quality system,IS014001:2015 environmental management system, lSO/TS16949:2016 Qualitymanagement system.

Other Things about Our Magnet Manufacturing

FAQs

Find answers to commonly asked questions about our magnetic solotions!

Our Customers & Factory

Jiada was founded in 1998, has been committed to the high quality wireless charger Ndfeb magnet researchand development, production and sales: it is one of the high-tech enterprises inGuangdong Province, with an annual output of 5000 tons of sintered Ndfeb capacity.

Thanks to the complete guarantee system, product quality is reliable. Adhering to thequality policy of “taking customer demand as the starting point, customer satisfaction asthe goal, continuous quality improvement as the driving force, and the best reputation asthe challenge”, jiada employees rely on advanced management concepts and perfectmanagement system.

Get In Touch

Dear friends, If you’d like clarification about our custom neodymium magnet manufacturing service or wholesale service, then we’d love to answer your questions.