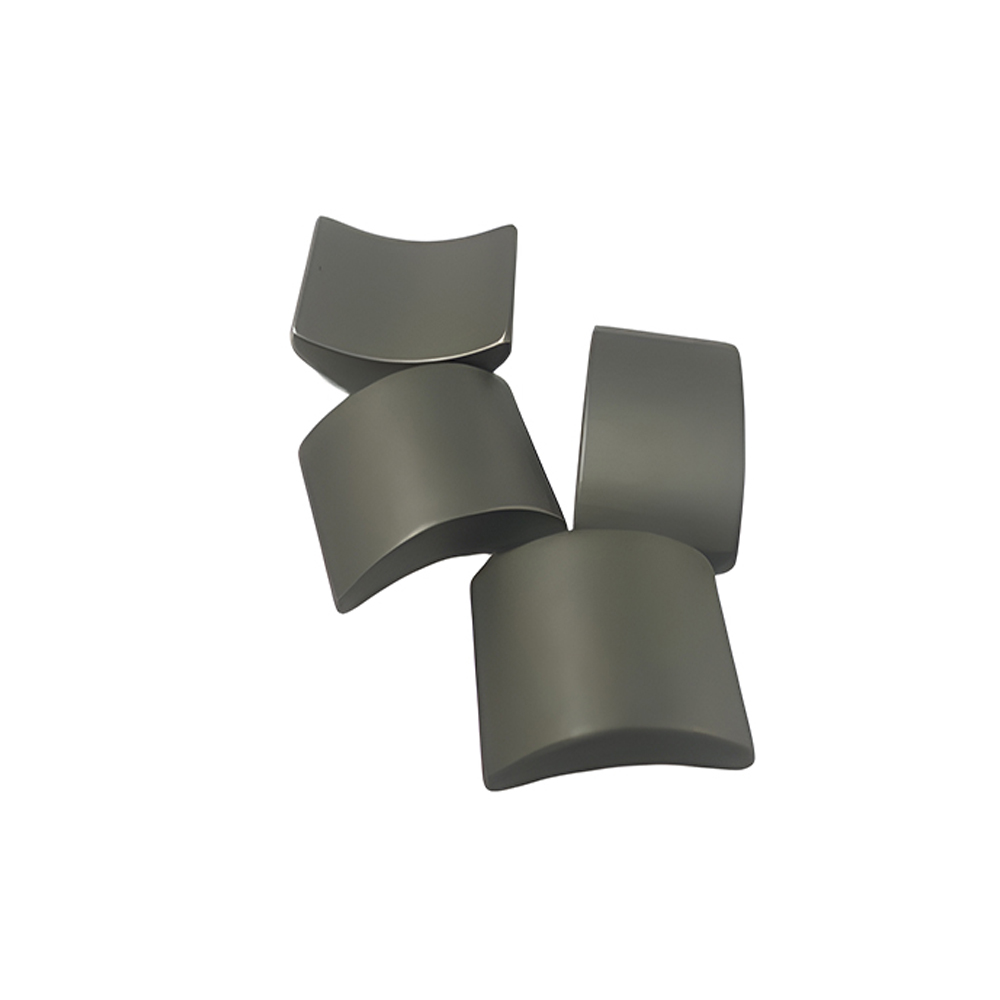

Custom neodymium magnets

What are NdFeB magnets?NdFeb (neodymium-iron-boron) magnets are currently the strongest permanent magnetic material, composed of neodymium, iron, and boron. With exceptionally high magnetic energy product and coercivity, they are known as the “King of Magnets” and are widely used in motors, wind power generation, electronic devices, and medical equipment. They are manufactured through two main processes: sintered magnets, which offer superior magnetic performance but require anti-corrosion coatings, and bonded magnets, which are easier to process but have slightly weaker magnetic properties. However, NdFeB magnets also face challenges such as oxidation susceptibility, demagnetization at high temperatures, and heavy reliance on rare earth resources. Current research focuses on improving their thermal stability, reducing rare earth usage, and developing recycling technologies to address cost and environmental concerns.

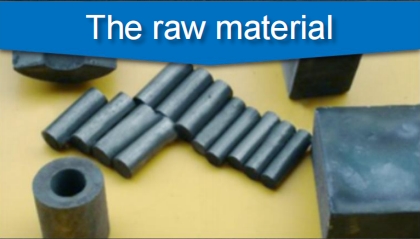

Sintered neodymium iron boron (commonly referred to as sintered NdFeB, with the chemical formula Nd₂Fe₁₄B) is a high-performance permanent magnet material manufactured through powder metallurgy processes. Its primary components are neodymium (Nd), iron (Fe), and boron (B), often supplemented with rare earth elements such as dysprosium (Dy) and terbium (Tb) to enhance coercivity and temperature stability. The microstructure consists mainly of a tetragonal Nd₂Fe₁₄B crystal phase, with grain boundaries enriched with rare earth elements to optimize magnetic properties.

“High-performance magnets are widely used in wafer manufacturing, aerospace, new energy vehicles, wind power, AI devices, medical equipment, motor drives, 3C electronics, food processing, and elevator systems, delivering critical power and precision control solutions across industries.”

Invisible purification, efficiently capturing fine iron contaminants to shield your machinery, reduce downtime, and cut costs.

For ultimate protection. Purify efficiently, last longer, and maximize your equipment’s performance.

Make learning fun! An interactive magnetic board for endless educational play.

Get creative with magnetic balls! Build, shape, and explore endless possibilities

Enable adaptive and precise gripping, revolutionizing industrial operations with a nimble “hand” for your smart production line.

Iron shell, powerful core: Multiplied magnetic force for lasting stability, enabling efficient and reliable industrial gripping and fixing.

PVC coated for impact and rust resistance, with color-coding for clear identification—delivering stronger, safer, and longer-lasting magnetic protection!

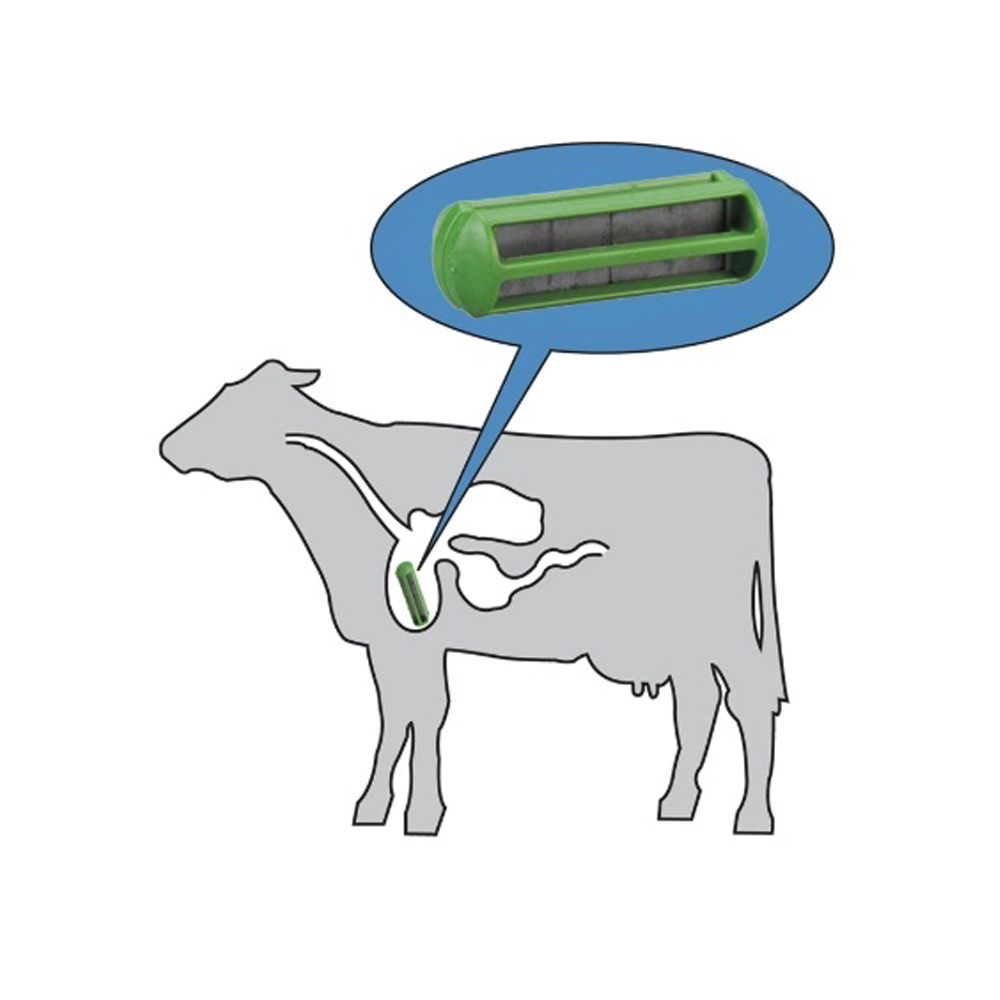

Safeguard cattle health, efficiently trap harmful metal debris, prevent stomach damage, and boost farming profitability!

Instantly secure, firmly discreet. Effortlessly switch your professional identity with seamless elegance!

Choose us, your reliable partner in non-demagnetization performance, and ensure every voyage returns with a full harvest.

Experience the grip that never quits. Our pot magnets deliver unmatched holding power.Don’t just hold it. Lock it down with magnetic force you can trust!

End clutter instantly! Mount tools neatly, access them in seconds, and create your efficient, clean workspace with a single snap

With reliable quality, scalable capacity, and rapid responsiveness, we pride ourselves on delivering customized high-performance magnet solutions. Contact us to discuss how we can support your projects!

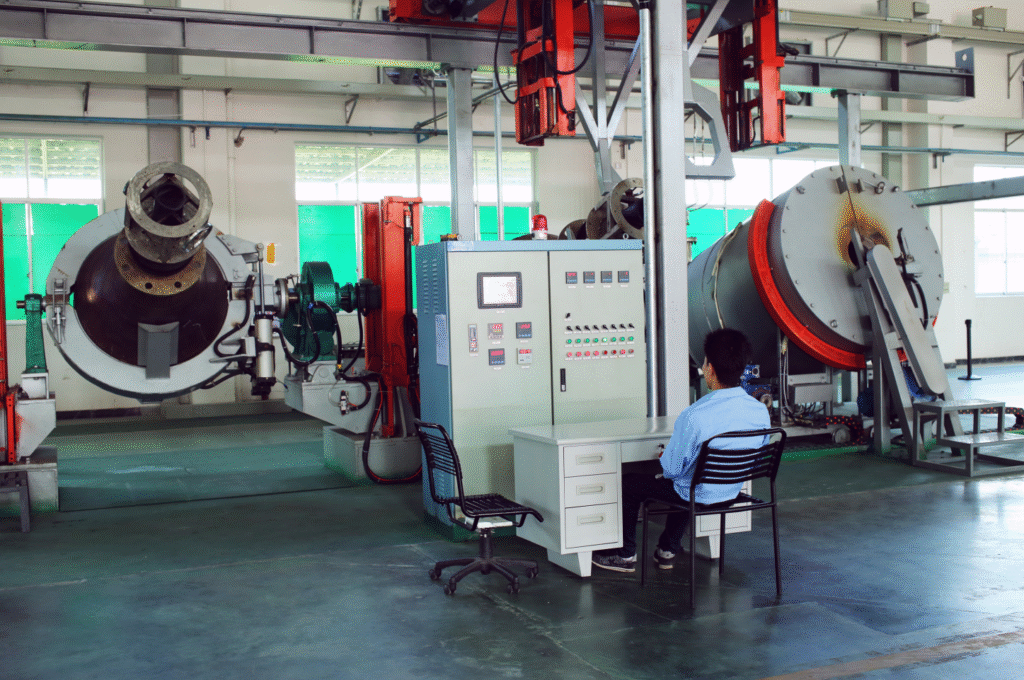

Large-Scale Production

Lean Management

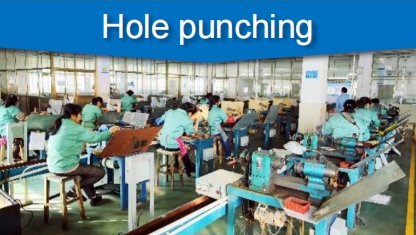

Human-Technology Synergy

Quality Assurance

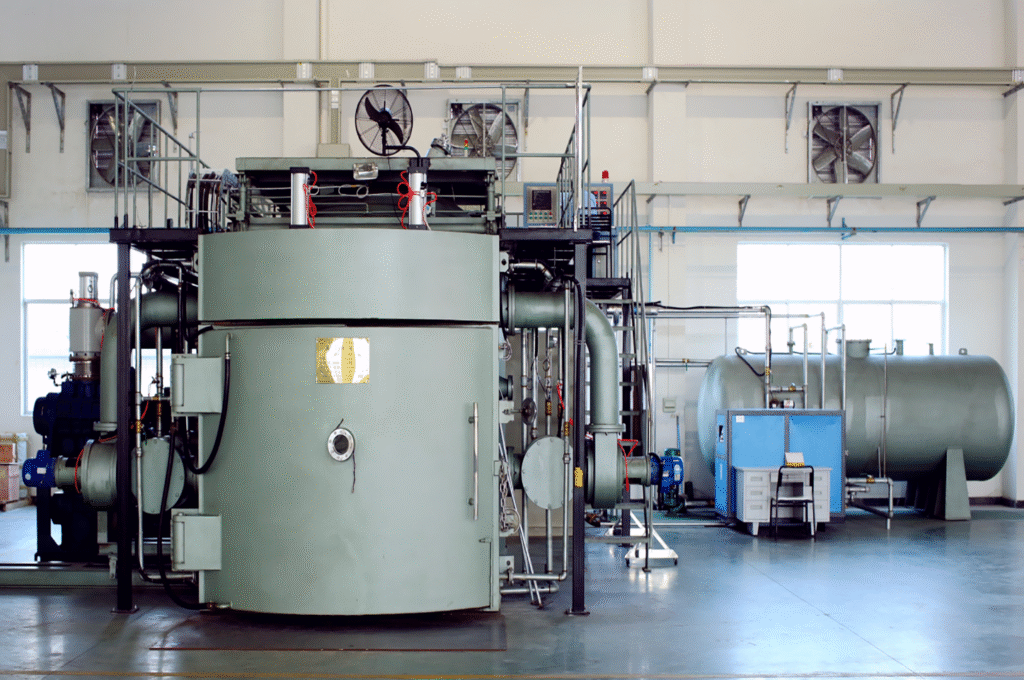

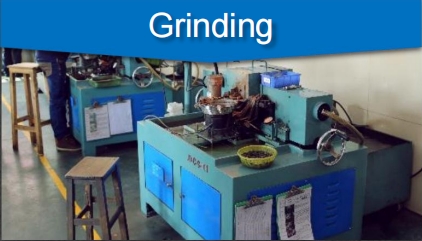

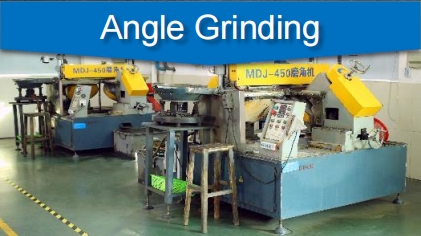

The manufacturing process of sintered neodymium iron boron (NdFeB) magnets involves several key steps: melting, powder milling, magnetic field-oriented pressing, high-temperature sintering, followed by heat treatment and surface coating. Precision machining techniques such as wire cutting or grinding are typically employed during processing. As a critical functional material in modern industry, continuous advancements in the performance and manufacturing processes of sintered NdFeB magnets are driving their expanding applications in high-end fields.

Vacuum rapid solidification furnace

Automatic multi-hydrogen crushing furnace

Airflow mill

Forming press

Vacuum sintering furnace

Test equipment

Neodymium iron boron (NdFeB) magnets exhibit high chemical reactivity, making them prone to oxidation and inherently brittle. To ensure durability, surface protection methods such as electroplating (e.g., nickel or zinc coating) or epoxy resin coating are essential.We offer comprehensive and highly flexible magnet customization services, ensuring that every one of your specific requirements is precisely met.

| Customer Concerns | Industry Standard | Our Advantages | Value to You |

|---|---|---|---|

| Lead Time | 45+ days for sintered NdFeB | ✅ Dongguan Rapid Sintering Line: 10-15 days ✅ Vietnam Warehouse: 20+ standard semi-finished products (72hr emergency service) | 50% faster project launch, market advantage |

| Certifications | Basic ISO 9001 only | ⭐ Dual Certifications: • ISO 9001 (Quality) • IATF 16949 (Automotive) | Direct Tier-1 supplier qualification, no additional audits |

| Supply Chain Security | Single sourcing, price volatility | 🔒 Dual-Source System: • Hitachi Metals (Japan, premium grade) • Chinese rare earth (cost-optimized) • 3-month strategic raw material reserves | 8-15% annual cost reduction, hedge against price surges |

| Cost Optimization | No transparent annual reduction | 💰 Written Commitment: • 3-5% annual price reduction (post-ramp-up) • 30-60 days payment terms | 20%+ lifetime savings, healthier cash flow |

| Brand Flexibility | Mandatory factory branding | 🏷️ Customization Services: • Neutral packaging (no traceability) • Full OEM support (labels/certificates) • "White label" solutions for distributors | Protect channel profits, brand control |

| Technical Support | Basic spec sheets only | 🛠️ Value-Added Services: • Free magnetic circuit design • Failure analysis lab • Multilingual documentation (EN/CN/VI) | Faster R&D cycles, lower trial costs |

JDM have successively passed lS09001 quality system,IS014001:2015 environmental management system, lSO/TS16949:2016 Qualitymanagement system.

Find answers to commonly asked questions about our magnetic solotions!

[JD]: Of course,We sincerely welcome your presence for guidance! During your visit, you will witness the entire process from raw material purification to finished product packaging. Our colleagues from the Vietnam office often also host international clients for visits.

Jiada was founded in 1998, has been committed to the high quality Ndfeb magnet researchand development, production and sales: it is one of the high-tech enterprises inGuangdong Province, with an annual output of 5000 tons of sintered Ndfeb capacity.

Thanks to the complete guarantee system, product quality is reliable. Adhering to thequality policy of “taking customer demand as the starting point, customer satisfaction asthe goal, continuous quality improvement as the driving force, and the best reputation asthe challenge”, jiada employees rely on advanced management concepts and perfectmanagement system.

Dear friends, If you’d like clarification about our custom neodymium magnet manufacturing service or wholesale service, then we’d love to answer your questions.